The Importance of Quality Control in Aviation Maintenance

The aviation industry is one where safety is paramount and quality control plays a critical role in ensuring the safety of passengers and crew members. A thorough quality control process helps identify potential issues, ensures that maintenance meets regulatory requirements, and ultimately prevents accidents. The consequences of poor quality control can be devastating, leading to equipment failure, injuries or fatalities, as well as expensive repairs or legal action.

Quality control involves a set of procedures aimed at ensuring that the products or services offered meet specific standards. In aviation maintenance, it means carefully monitoring all aspects of aircraft repair and maintenance, including personnel training, tool calibration, record-keeping practices and aircraft inspections.

Overview of Best Practices for Quality Control in Aviation Maintenance

To effectively manage quality control in aviation maintenance requires a comprehensive approach that addresses various aspects. A successful system should incorporate effective documentation and record keeping practices to enhance traceability and accountability while providing appropriate training programs for personnel.

Inspection procedures should also be robust to ensure that any defects are detected early enough before they escalate into more significant problems. In addition, it is essential to maintain tools, equipment and facilities regularly to prevent them from malfunctioning when needed most.

Conducting regular audits will help identify areas requiring improvement while providing insight into how effective existing procedures are at preventing defects. In this article's subsequent sections, we will delve deeper into each best practice's specifics by outlining what they entail and highlighting examples of successful implementation within aviation maintenance trade.

The Importance Of Quality Control In Aviation Maintenance

It cannot be overstated how critical quality control processes are to ensuring safe air travel operations. According to the FAA, 80% of accidents are caused by human error, including as mistakes committed during regular checks, inspections, and maintenance.

Hence, the rigorous adherence to quality control standards minimizes the risks of mistakes that could lead to fatalities or equipment failure. Effective quality control procedures can also mean a reduction in operating costs.

For instance, early detection and correction of small defects can prevent more significant issues that may require extensive repairs and replacements. Consequently, this helps extend the lifespan of aircraft components while reducing downtime losses associated with extended repair periods.

It is also worth noting that quality control is mandatory for all aviation industry stakeholders. The FAA requires all operators to follow specific guidelines that help ensure compliance with federal regulations regarding aviation safety standards.

Overview of Best Practices for Quality Control in Aviation Maintenance

Implementing robust quality control practices within aviation maintenance can be daunting without a clear roadmap outlining best practices' specifics. As earlier noted, such a roadmap should consist of documentation and recordkeeping practices coupled with appropriate personnel training programs. Effective inspection procedures should also feature prominently within any quality control system as they constitute an important element in preventing defects from escalating into more significant issues or accidents.

Maintaining tools and equipment regularly is critical to ensuring they operate at optimal conditions when required to prevent potential hazards or accidents. Regular audits provide valuable feedback insights into how effective systems are performing while identifying areas requiring improvement.

Quality Control Standards

What are Quality Control Standards in Aviation Maintenance?

Quality control standards are the guidelines and regulations that ensure aviation maintenance is performed to a specific level of quality. These standards outline specific procedures and protocols that must be followed to guarantee that every aspect of the maintenance process is completed to a high standard.

Adhering to these standards is critical, as they help ensure that aircraft components and systems are functioning as intended, reducing the likelihood of accidents or malfunctions. The Federal Aviation Administration (FAA) sets forth quality control standards in Part 145 of its regulations.

This section outlines specific requirements for maintenance, preventive maintenance, rebuilding, and alteration on certificated aircraft and related parts. There are also numerous other industry-recognized organizations with their own sets of quality control standards, such as the European Aviation Safety Agency (EASA), International Air Transport Association (IATA), and International Civil Aviation Organization (ICAO).

Importance Of Adhering To Quality Control Standards

Adhering to quality control standards is essential in aviation maintenance for several reasons. First and foremost, adhering to these guidelines ensures that all components are inspected thoroughly, repaired or replaced when necessary, and tested before being returned to service.

This approach reduces the likelihood of malfunctions during flight operations due to poor workmanship or unperformed inspections. Moreover, adhering to quality control standards helps establish consistency within aviation maintenance practices across industries.

It ensures that all companies holding certifications operate under similar guidelines with an emphasis on safety above anything else. Following quality control standards can help protect your organization from liability issues should an accident occur due to negligence or substandard practices.

Examples Of Quality Control Standards In Aviation Maintenance

One example of a widely used set of quality control standards in aviation maintenance is the ISO 9001 standard. This standard outlines requirements for a Quality Management System (QMS) and requires organizations to establish procedures for maintaining high-quality products and services. This system includes the establishment of quality objectives, quality policies, monitoring of customer satisfaction, and regular audits of the QMS.

Another example is ATA Specification 100. This specification outlines detailed guidelines for aircraft maintenance documentation, including work orders, technical data, revision control, and other elements essential to ensuring that every aspect of the maintenance process is documented thoroughly.

In addition to these examples, there are other sets of standards specific to certain areas such as NADCAP (National Aerospace and Defense Contractors Accreditation Program), which focuses on special processes like non-destructive testing or heat treatment. Adhering to each set of standards provides an extra layer of safety in aviation maintenance operations.

Documentation and Record Keeping

Importance of Documentation and Record Keeping in Aviation Maintenance

The importance of documentation and record keeping in aviation maintenance cannot be overstated. Detailed and accurate records are vital to the safety, efficiency, and compliance of aviation operations.

They allow for traceability, accountability, analysis, and improvement. They provide evidence that all required tasks were completed, by whom, when, why and how.

They facilitate planning, scheduling, forecasting, reporting and decision making. They also help to avoid legal disputes or liabilities.

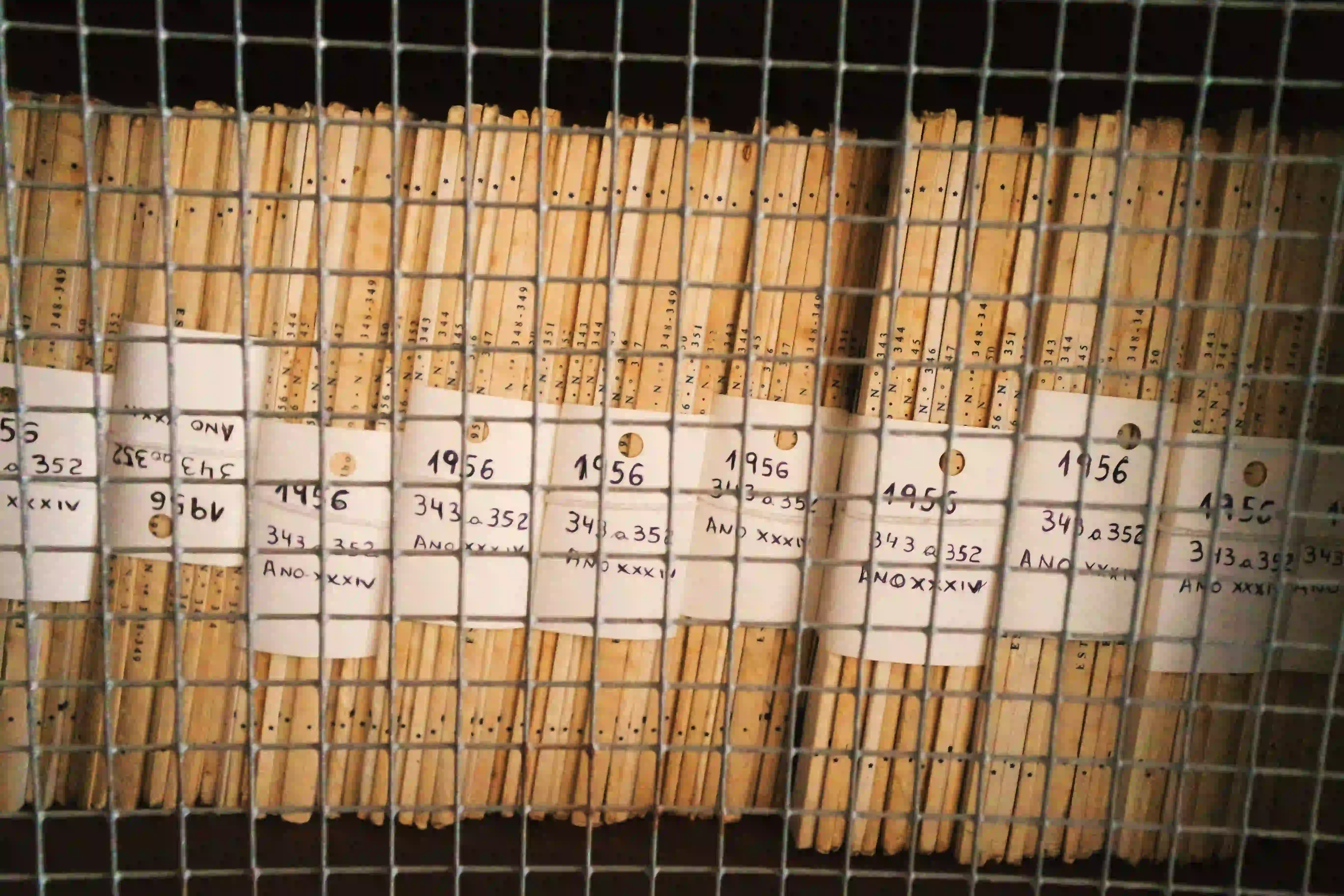

Documentation refers to the creation or collection of any written or electronic records related to aviation maintenance activities such as work orders, inspections reports, logbooks updates , parts orders etc.. Records refer to the organized storage and retrieval of those documents over time according to regulatory requirements . For example 14 CFR Part 43 Appendix B lists minimum items that have to be recorded during maintenance activities on aircraft registered in the United States.

Best Practices for Maintaining Accurate Records

Maintaining accurate records can be challenging due to the volume and complexity of data generated by aviation maintenance activities . However , there are several best practices that can help :

Use standard formats : use templates or forms that follow industry standards or regulatory requirements so that all required information is captured consistently.

Create comprehensive entries : ensure each entry includes relevant details such as date/time stamp , job description , person who performed the task , equipment used , parts installed etc.. avoid abbreviations or vague terminology.

Assign unique identifiers : use unique identifiers for each aircraft or component (serial numbers) as well as each task (work order number) so that traceability is possible throughout its lifecycle.

Maintain a centralized database : Keep records in a centralized database that is accessible to all relevant personnel and that can generate reports or alerts when needed . Avoid using paper records or spreadsheets that can be easily lost, damaged or corrupted.

Examples of Documentation and Record Keeping Practices

Examples of good record keeping practices in aviation maintenance include :

Electronic Maintenance Records (EMR): A single software platform to manage and store all maintenance data. EMRs are searchable, sortable, updatable, and scalable. They can include modules for tracking work orders, inventory management , regulatory compliance checks etc...

Digital Signatures: electronic signatures capture unique identifiers for technicians who performed tasks on aircraft systems so that accountability for tasks is established.

Barcode Scanning : using barcodes to track parts inventory , reduce errors in data entry and speed up record keeping processes.

Data Analytics : by mining maintenance records for patterns or trends , organizations can identify areas where quality control improvements could be made before they become safety issues.

Documentation and record-keeping are critical components of quality control in aviation maintenance. They provide traceability, accountability, analysis, and improvement opportunities while ensuring compliance with regulatory requirements. The implementation of best practices such as the use of standardized forms/templates , comprehensive entries , unique identifiers , centralized databases and digital tools can help ensure the accuracy , completeness , timeliness and usefulness of aviation maintenance records.

Training and Education

Knowledge is Power: The Importance of Training and Education for Aviation Maintenance Personnel

The aviation industry is constantly changing, which means that maintenance personnel must be up-to-date with the latest technology, regulations, and safety procedures. This is why training and education are essential in aviation maintenance.

Well-trained personnel can detect potential problems before they occur, keep aircraft safe for passengers, and ensure compliance with regulatory requirements. Investing in training and education programs can have a significant impact on the quality of work performed by maintenance personnel.

Quality training develops skills to perform required tasks to set industry standards. These standards are crucial to maintain consistency in quality work performance across different teams in an organization.

Best Practices for Providing Training and Education to Personnel

Providing effective training and education requires a multi-faceted approach that includes classroom instruction, hands-on experience, mentoring programs, workshops, seminars, online courses and conferences. A blended approach ensures that all learning styles are catered for adequately. Implementing a continuous improvement program that provides ongoing education helps the staff members develop their skills from time to time by keeping them updated with new trends in the industry or introducing new technologies within the organization.

Supervisors should also encourage personnel to participate in training opportunities. Offering incentives such as bonuses or promotions can motivate staff members further.

Examples of Successful Training Programs

One example of a successful training program is Embry-Riddle Aeronautical University's Aviation Maintenance Science (AMS) program. This four-year bachelor's degree program prepares students for careers as skilled professionals throughout the aviation industry. Another successful program is Delta Air Lines' Technical Operations College.

This facility offers more than 100 courses designed specifically for Delta’s technical operations professionals covering Aircraft Systems Maintenance Operations (ASMO), Avionics Systems Maintenance Operations (AVSMO), Non-Aircraft Maintenance Operations (NAMO), and Technical Operations Leadership (TOL). Both these programs exemplify the importance of the aviation industry investing in training and education opportunities for their personnel to maintain quality control standards.

Conclusion

Training and education are vital aspects of maintaining quality control in aviation maintenance. It provides personnel with new skills, knowledge, best practices, and up-to-date industry standards.

Implementing a continuous improvement program that includes both classroom instruction as well as hands-on experience can guarantee better results from personnel. Organizations should invest in training programs adequately to ensure they remain competitive and keep their personnel up-to-date with changes happening within the sector.

Inspection Procedures

The Importance of Inspection Procedures in Ensuring Quality Control

Inspection procedures are a crucial aspect of quality control in aviation maintenance. By conducting thorough and regular inspections, potential issues can be identified and corrected before they cause any serious problems.

This helps ensure the safety of both the aircraft and its passengers, as well as minimizing the risk of costly downtime due to unexpected maintenance issues. Proper inspection procedures also help maintain compliance with regulatory agencies such as the Federal Aviation Administration (FAA).

Failure to comply with regulations can result in steep fines or even a loss of operating certificate. Therefore, adherence to inspection procedures is vital for an aviation maintenance organization's success.

Best Practices for Inspection Procedures

To ensure proper inspection procedures are followed, it is important to establish clear guidelines and expectations. These guidelines should define what must be inspected, how it is inspected, and who is responsible for conducting inspections.

One best practice for inspection procedures is to use a detailed checklist that covers all aspects of the aircraft. The checklist should be regularly reviewed and updated based on any changes to regulations or manufacturer recommendations.

It should also include specific instructions on how each item should be inspected. Another best practice is to assign dedicated personnel specifically responsible for conducting inspections.

These individuals should receive specialized training on inspection techniques and regulations, ensuring their ability to conduct thorough and accurate inspections. Incorporating technology such as digital checklists or automated maintenance tracking systems can streamline inspection procedures by reducing human error and providing real-time updates on aircraft status.

Examples of Successful Inspection Procedures

One example of successful inspection procedures can be found at Southwest Airlines. The airline's maintenance program incorporates comprehensive inspection protocols that cover everything from visual checks to advanced diagnostic testing.

Their rigorous attention to detail has helped them maintain one of the best safety records in the industry. Another example comes from Delta Air Lines, which utilizes a unique program called "the Delta TechOps Way." This program emphasizes the importance of continuous improvement in all aspects of maintenance, including inspection procedures.

Through this focus on quality control, Delta has been able to maintain an impressive level of safety and reliability. Inspection procedures are a critical component of quality control in aviation maintenance.

By establishing clear guidelines and utilizing best practices such as detailed checklists and specialized personnel, organizations can ensure the safety and reliability of their aircraft while maintaining compliance with regulatory agencies. Successful examples from industry leaders such as Southwest Airlines and Delta Air Lines serve as models for other organizations striving to improve their own inspection procedures.

Tools, Equipment, and Facilities Maintenance

The Importance of Tools, Equipment, and Facilities Maintenance

The importance of maintenance for tools, equipment and facilities in aviation maintenance cannot be overstated. Machines that are not well-maintained can fail at any time during operations causing safety and quality issues.

Proper maintenance ensures that the tools and equipment function optimally while maintaining their reliability, accuracy, and precision. It also helps to prevent accidents associated with equipment malfunctioning.

Facilities also need regular maintenance to ensure they remain safe for personnel working in them. This includes checking the electrical wiring systems for loose connection points or frayed wires that could pose a significant risk to employees working within the facility.

Furthermore, a poorly maintained facility can lead to contamination of workspaces or even air conditioning systems; this is particularly important in aviation where air quality is crucial in ensuring a safe flight experience for passengers. Regular cleaning including disinfection of surfaces ensures workspaces remain clean reducing the risks associated with microbial growth and cross-contamination.

Best Practices for Maintaining Tools, Equipment, and Facilities

To ensure tools, equipment, and facilities are well-maintained adhere to these best practices:

Scheduling regular inspections: regular inspections ensure timely detection of faults before they become critical.

Establishing clear procedures: this should include maintenance schedules as well as procedures for routine cleaning.

Maintaining records: document all inspections performed on any tool equipment or facility along with action taken when correcting any issues found.

Cross-training staff: proper training on how to maintain tools ensures employees have the necessary skills needed to operate machines safely.

Utilizing preventative measures: implement measures such as scheduled replacement of parts before anticipated wear and tear occurs as well as utilizing protective measures such as covers that protect equipment from dust and other elements.

Examples of Successful Tools, Equipment, and Facilities Maintenance

One example of successful facility maintenance is the Delta TechOps facility in Atlanta, which is known for its world-class overhaul, maintenance, and repair services. They are able to maintain their facilities to the highest standards by using regular inspections along with detailed cleaning procedures.

Another example is Alaska Airlines who were able to reduce costs associated with equipment maintenance by replacing worn-out parts before they failed entirely. This approach helped reduce the number of unscheduled maintenance issues and improve overall reliability.

The FAA also conducts regular audits on airlines' maintenance practices. One such audit found that United Airlines was maintaining their equipment to the highest standards by carrying out regular inspections as well as ensuring their staff were properly trained on how to maintain all their tools and equipment.

Regular maintenance of tools, equipment, and facilities ensures safety while reducing downtime caused by unexpected failures. The best practices discussed above should be implemented in all aviation operations to ensure optimal performance at all times.

Quality Control Audits

Importance of Quality Control Audits

Quality control audits are essential for maintaining a high level of safety in aviation maintenance. They ensure that the quality control measures put in place are effective and being followed correctly. Without regular audits, there is a risk that small issues could go unnoticed and lead to more significant problems down the line.

In addition to ensuring safety, quality control audits also help maintain compliance with regulations set forth by organizations such as the Federal Aviation Administration (FAA). These regulations often require specific quality control measures be implemented and followed, and regular audits ensure that these measures are being met.

Furthermore, quality control audits can identify areas for improvement within an organization's quality control processes. By conducting regular audits, an organization can identify potential issues before they become significant problems and work towards improving their overall quality control procedures.

Best Practices for Conducting Quality Control Audits

When conducting quality control audits, it is essential to have a clear plan of action in place beforehand. The following best practices can help ensure successful audit procedures:

1. Develop a detailed checklist: A checklist should be created beforehand which outlines all the essential aspects of an audit so that nothing is overlooked.

2. Assign qualified personnel: The personnel assigned to conduct the audit should be qualified and trained in both auditing techniques and aviation maintenance procedures.

3. Use samples: It's important to use representative samples when conducting an audit to obtain accurate results.

4. Document findings: All findings should be thoroughly documented with details regarding any discrepancies uncovered during the audit process.

5. Follow up on discrepancies: Actions should be taken quickly when discrepancies are discovered during an audit process so they can be resolved efficiently before becoming bigger issues.

The Concluding Thoughts

Quality control audits play a crucial role in ensuring safety and compliance within aviation maintenance, identifying areas for improvement, and assuring equipment and facilities meet industry standards. By implementing best practices such as developing a detailed checklist, assigning qualified personnel, using samples, documenting findings, and following up on discrepancies found during an audit process can help organizations conduct successful quality control audits. These audits benefit the aviation industry as a whole by ensuring the safety of passengers and equipment while maintaining compliance with important regulations.